Personal Life

Different Types Of Kitchen Knives Materials

Professional cooks will need a sharp and edgy knife to [ ]

Personal Life

Get your Most Captivating Recipes Today

Do you do catering may be or do you love trying new and [ ]

Personal Life

Expert Advice: Sewed-In or Glued Lace Front Wig

After finding a perfect lace wig, you are left with the [ ]

Personal Life

Do You Know How Can You Use the Paper Dollies

If you are looking to make different crafts using golde [ ]

Personal Life

What to Look for in the Best Dog Bandana

A bandana is one of the top fashion accessories you can [ ]

Personal Life

Do You Know How To Wear Frontal Closure Wig?

How to wear your 4 4 lace closure wig perfectly? T [ ]

Personal Life

Heart-shaped gift item necklaces with stone detailing

Ineffabless Birthstone detailed customizable pendants w [ ]

Personal Life

Top Reasons to Purchase Electronic Gadgets Online

Many customers avoid purchasing electronic gadgets onli [ ]

Personal Life

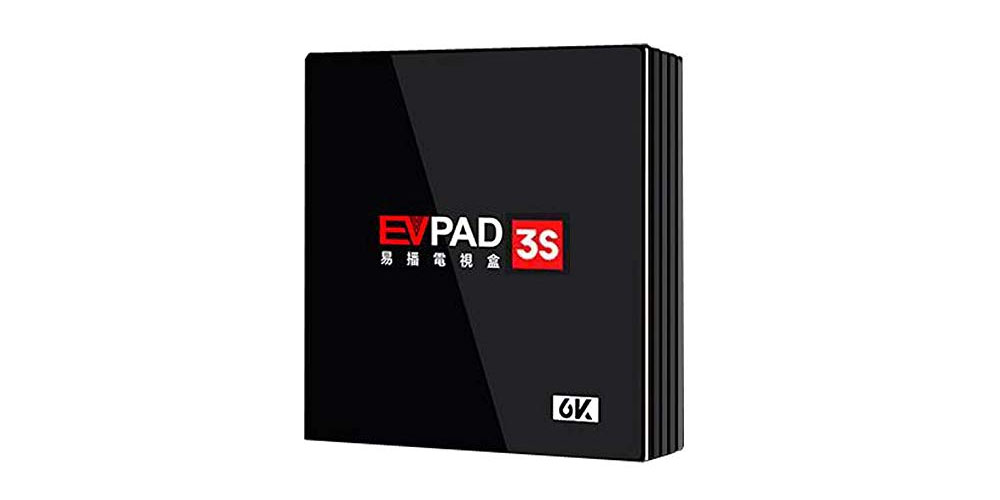

Tips for shopping for the best Android TV box

Evpad Indonesia is an online store where you can purcha [ ]

Personal Life

Various Locket Styles for Your Locket Necklaces

A locket is a pendant attached to a chain and comes in [ ]

Personal Life

Everything you need to know about Giraffe Tools

Hoses and hose reels work hand in hand. While hoses can [ ]

Personal Life

The Wonder of Retractable Garden Hose Reel

Each and every day the new products are emerging on the [ ]